- Cabinets

-

-

SMT Reel Storage

(Coming Soon)

Waffle Pack Storage

(Coming Soon)

-

-

- Hand Tools

-

- Chairs

-

- Lift Carts

Nitrogen Gas Distribution Diagram

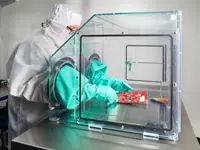

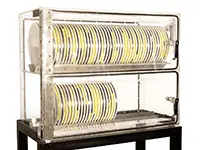

Desiccator Ultra Nitro-Flow System

TDI Acrylic Desiccators provide a clean dry atmosphere to protect moisture sensitive materials/components in storage. Our cabinets require a constant dry nitrogen gas supply to maintain low moisture conditions. Connect the gas supply to the nitrogen flowmeter on the desiccator cabinet. The flowmeter regulates the nitrogen gas flow (cubic feet per hour) to the plenum chamber, with the nitrogen gas distributed uniformly through the perforated inside wall of the plenum chamber into each compartment.

Acrylic Desiccators

All TDI Acrylic Desiccators are constructed with Ultra Nitro-Flow compartment flow-throughs, which achieve a single pressure and atmosphere condition throughout the desiccator. This unique design allows maximum gas flow in both the vertical and horizontal directions and reduces higher moisture humidity conditions between compartments.

Stainless Steel Desiccators

Our multi chamber stainless steel desiccators now also feature the Ultra Nitro-Flow. This allows for a single bleeder valve per multiple compartment desiccators. This eliminates the need for expensive outlet valves for each compartment, required in typical competitor desiccators. The bleeder valve is located in the bottom of the lowest compartment and serves as an efficient outlet drain for the heavier high moisture atmosphere within the cabinet. This design also allows for a single Nitro-Save® for multiple compartment desiccators.

Why Choose a TDI Desiccator?

The Ultra-Nitro Flow system offers a highly efficient and economical design.

In cases where the Nitro-Save® is running when the doors are open, a positive pressure of nitrogen flow extends throughout the desiccator plenum wall to all compartments and exits through the open door(s). This precludes any higher humidity room air back fill into the desiccator.

The desiccator cabinet and room atmospheric pressures are similar when the pre-set RH% settings have been achieved. Air movement between the compartments and the room is slight when the doors are opened. During the brief time frame of exposure, there is minimal RH% level increase in the desiccator.

Clean rooms generally operate in a 45-55% RH range and this would represent the highest increase condition possible inside an open desiccator compartment.

Competitive acrylic desiccators brands offer expensive moisture control systems that are dependent on electro-mechanical switches to control moisture flow. These systems are subject to maintenance with repair / replacement in the long run with compromised reliability. Ironically, most desiccators in service have no RH% moisture control at all and often consume excess nitrogen to compensate.

The Nitro-Save® Humidity Control Monitor significantly reduces the nitrogen required to maintain pre-set relative humidity (RH) in desiccators. It includes a solenoid control valve and internal sensor system. This regulates the nitrogen flow in response to the high humidity set point.