Application Specific Desiccator Cabinets

Application specific desiccator cabinets for storage of specific products. This includes wafer carriers, SMT reels, waffle packs, and bonding wire spools. Providing the highest quality and most durable construction to meet the requirements for cleanroom and assembly component storage applications. TDI application specific desiccator cabinets are designed for in-line nitrogen or a clean dry air (CDA) source. This will furthermore assure adequate gas pressures (PSI – source to desiccator) and adequate gas volume for continued humidity control operation of the desiccator.

Waffle Pack Storage

Waffle pack desiccator cabinets provide the highest density storage for 2″ and 4″ waffle packs. Twice the storage capacity of competitive brand desiccators!

Constructed with 1/4″ clear or static dissipative acrylic material (non-out-gassing). Sliding drawers offer easy access, while at the same time adjustable dividers allow for diversity in storing either waffle pack size and in various quantities. As a result, these desiccators provide the highest density storage for waffle packs! Of course, these desiccators also provide a clean, dry environment. For use with in-line Nitrogen or Clean Dry Air (CDA).

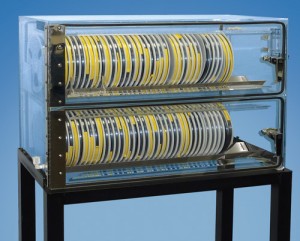

SMT Reel Storage

TDI’s SMT reel desiccator cabinets for high-density storage in a clean, dry nitrogen atmosphere. For storage of SMT reels up to 13” diameter. Slide drawer trays offer easy access for reel handling. Furthermore, upright reel storage provides efficient use of compartment space. As a result, these desiccators provide high-density storage while taking up less space. Custom designs available for mixed 7″ and 13″ size reels (please note in comments).

Storage of SMT reels prior to loading onto tape-on-reel feeders used with pick and place machines for component parts handling in electronics assembly applications. Continuous N2 gas source for best humidity control. As a result, no added desiccants, driers or exhaust systems are required.

Wafer Storage Desiccator Cabinets

By and large, wafer fab is a procedure made up of many repeated sequential processes in order to produce complete electrical or photonic circuits. TDI wafer storage desiccator cabinets provide high-density storage of up to 8” diameter silicon wafers in standard wafer carriers (boxes). For wafer carriers 11”W x 11”D x 10”H maximum. These specialized desiccator cabinets feature a 27″ depth to accommodate 4 wafer carriers per compartment. In addition, 3/8″ extra thick floors provide a higher weight capacity. As a result, the maximum capacity is increased to 40 lbs. maximum per compartment.

Bonding Wire Storage

Bonding wire manufacturers recommend storage of wire with spools stored upright to avoid wire sag on the spool. Accordingly, these bonding wire desiccator cabinets provide this spool orientation feature. In addition to a clean, dry nitrogen atmosphere.