DESICCATOR CABINETS / DRY BOXES

Desiccator cabinets provide a clean, dry environment for critical low RH% cleanroom as well as assembly component storage applications. Each compartment has a spring-loaded door latch and gasket for an air-tight seal. Continuous stainless steel hinge provides maximum support for chamber doors. In addition, these desiccator cabinets feature our unique Ultra Nitro-Flow System. This feature includes cutouts in the walls and floors of each chamber for even nitrogen distribution throughout multiple chamber desiccators. Finally, the perforated plenum chamber purges nitrogen into all compartments at an even rate. Equally important, these desiccators feature a removable back plenum wall for easy maintenance.

Available in acrylic, static dissipative acrylic, and stainless steel.

Acrylic Desiccator Cabinets

All acrylic desiccators include our unique Ultra Nitro-Flow System for even nitrogen distribution. Sizes include 1 to 12 chambers.

Clear Acrylic Desiccators

Standard Features:

- Constructed of 1/4″ thick acrylic, an inherently inert and clean non-out-gassing material.

- Unique desiccator door design, allowing for minimum door weight in addition to maximum seal integrity and durability.

- Ultra Nitro-Flow with notched compartment walls and floors for uniform humidity control in all compartments.

- Optional adjustable perforated stainless steel or solid acrylic shelves.

- Spring loaded door latches and continuous stainless steel door hinges.

- Recessed closed cell neoprene gasket insures integrity in placement.

- Continuous in-line nitrogen (N2) or clean dry air (CDA) required.

ESD Safe Static Dissipative Acrylic Desiccators:

Includes all Above Listed Features and Also:

- Provides complete electrostatic discharge protection for ESD sensitive clean room and assembly component storage.

- Constructed with 1/4″ thick static dissipative acrylic. Prevents build-up of static charge and accumulation of harmful contamination.

- Electrostatic decay in less than 0.05 seconds per Federal Test Standard 101C, Method 4046.1.

- Surface resistivity 106-108 Ohms/sq.

- Stainless shelf racks, shelves, and plates are commonly grounded to the desiccator and wire connected to hard ground.

- Plates are recommended on the floor of each compartment to enhance grounding and protect the acrylic surface from abrasion.

Desiccator Options:

- Plenum Chamber, Flowmeter & Bleeder Valve

- Heavy Duty Shelf Racks & Acrylic or Stainless Steel Shelves

- Stainless Steel Plates & Grounding

- Nitro-Save® or Hygrometer

- Camlocks & ID Pockets

- Stand with Lockable Casters or Levelers

Desiccator Cabinets – Frequently Asked Questions

Stainless Steel Desiccators

Stainless steel desiccators provide clean, high-density storage for both cleanroom and assembly applications. Compared to acrylic desiccators, stainless steel provides maximum weight capacity and long-term durability.

Compare Stainless Steel Models & Get a Quote

Available in a Table Top single chamber model, Stacked Modules or Multi-Chamber Models to fit your storage needs. These desiccators have tempered glass doors with heavy-duty stainless door frames.

In order to achieve a single pressure throughout the desiccator cabinet, we construct the multi-chamber models with notched chamber walls and floors.

This allows gas to flow in both vertical and horizontal directions, thus eliminating the need for outlet valves for each compartment. Therefore, a desiccator with notched chambers provides you with a less expensive and more convenient choice.

Nitro-Save® Humidity Control Monitor Solid-State Sensor for Accurately Controlling Pre-Set RH

The primary purpose of desiccators is to establish precise relative humidity levels to protect moisture sensitive materials in a clean environment. TDI has developed an economic, solid state system that accurately controls humidity and significantly reduces nitrogen consumption.

The Nitro-Save® Humidity Control Monitor significantly reduces the nitrogen required to maintain pre-set humidity (RH%) in TDI’s Desiccator Cabinets up to 90%+ reduction in nitrogen consumption in many applications. This unit displays temperature as well, but it is not calibrated to monitor it.

- Nitro-Save systems are specifically designed to work with TDI Desiccator Cabinets

- Accuracy: ±2% at 3-80%RH

- Silent Operation with High Reliability and No Electromechanical Switches

- Solenoid Control Valve & Internal Sensor System

- Sensor System Activates Solenoid as N2 Flow Required

- Continuous In-Line Nitrogen or Clean Dry Air Required.

- Must Operate at 80 PSI (min) to 100 PSI (max) for Optimum Performance

- Reduces Nitrogen Consumption up to 90% (20%RH) in Many Applications

Electrical Requirements:

- Input: 120VAC / 60Hz / 10W (In-House Adapter may be Required for Foreign Voltage)

- Output: 9VDC / 500mA

- Power Plug – ETL Approved per UL Standard

Wafer Storage Desiccator Cabinet

View Wafer Storage Models & Get a Quote

Our heavy-duty wafer storage desiccator cabinets allow for high-density storage. Utilizing as much compartment space as possible to fit your wafer carriers. These desiccators are designed to fit up to 8″ diameter silicon wafers in standard wafer carriers (boxes). Furthermore, the wafer carriers themselves can be up to 11”W x 11” D x 10”H.

These specialized desiccator cabinets feature a 27″ depth to accommodate four wafer carriers per compartment. In addition, these desiccators offer 3/8″ extra thick floors, to allow for a higher weight capacity of up to 40 lbs. per compartment (evenly distributed).

Wafer fab is a procedure made up of many repeated sequential processes in order to produce complete electrical or photonic circuits.

Waffle Pack Desiccator Cabinet

View Waffle Pack Storage Models & Get a Quote

These 2” and 4” waffle pack desiccators offer high-density storage in a clean, dry nitrogen atmosphere. Additionally, stainless sliding drawers offer easy access. Finally, adjustable dividers allow diversity for storing either waffle pack size and in various quantities. As a result, these desiccators offer twice the storage capacity of competitive brands!

All TDI acrylic desiccators utilize 1/4″ acrylic, a clean and non-out-gassing material. All cabinets include unique cabinet door design for minimum door weight while at the same time offering maximum seal durability and integrity.

Another important feature, SD acrylic waffle pack storage desiccator cabinets offer complete ESD protection for static sensitive assembly and clean room component storage.

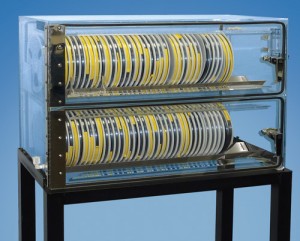

Tape & Reel Storage / SMT Reel Storage

View Tape & Reel Desiccator Models & Get a Quote

TDI’s SMT reel storage desiccator cabinets are perfect for high-density storage in a clean, dry nitrogen atmosphere. These desiccators are designed for SMT reels up to 13” in diameter. Our unique slide drawer trays offer easy access for reel handling.

Another unique feature is the upright positioning of reel storage which provides the most efficient use of compartment space. Due to the variety of reel sizes, custom designs available for mixed 7″ and 13″ size reels (please note in comments).

Storage of SMT reels prior to loading onto tape-on-reel feeders used with pick and place machines for component parts handling in electronics assembly applications. A continuous N2 gas source is required for best humidity control. Another noteworthy feature, these desiccator cabinet models require no desiccants, driers or exhaust systems.

Bonding Wire Storage

View Bonding Wire Storage Models & Get a Quote

Bonding wire storage desiccators provide high-density spool storage as well as a clean and exceptionally dry environment. Industry bonding wire manufacturers recommend storage of wire with spools stored upright in order to prevent wire sag on the spool. Therefore, all TDI bonding wire desiccators provide this spool orientation. Finally, this model of desiccator cabinet is available in clear acrylic only.